PPC Module

EBS 5.0 assists you to plan and produce the right quantity driven by Sales Forecasts / requirements with improved productivity

Production means the process of producing the products manufactured through production process. Which starts with sending the booked order of customer for production in the form of production order, in another case production order is also made for producing goods for maintaining the minimum level of finished goods stock. Once production order is received by the production department the raw material requisition is send to the store department for the collection of required resources for starting the production process.

Production Process Wise Control Job Order

There are two types of production order which are as follows:

Production Order against sale order.

Production order for maintaining minimum Stock.

Production order for Stock

The Production order against sales order is made for producing the product for making the finished goods stock available for dispatch against the specified sale order.

Job to Position detail

Job to position detail is made for splitting the Job id manually into lots in order to plan according to the line capacity so the planning can be made on the basis of it.

Daily Production Planning

The Daily Production Planning is made for daily activity planning for Daily Production on the basis of Production order, Position on the hand for planning.

Material Requisition

The Material requisition is used for making production requisition automatically on the basis of the selected planning qty product design bill of material.

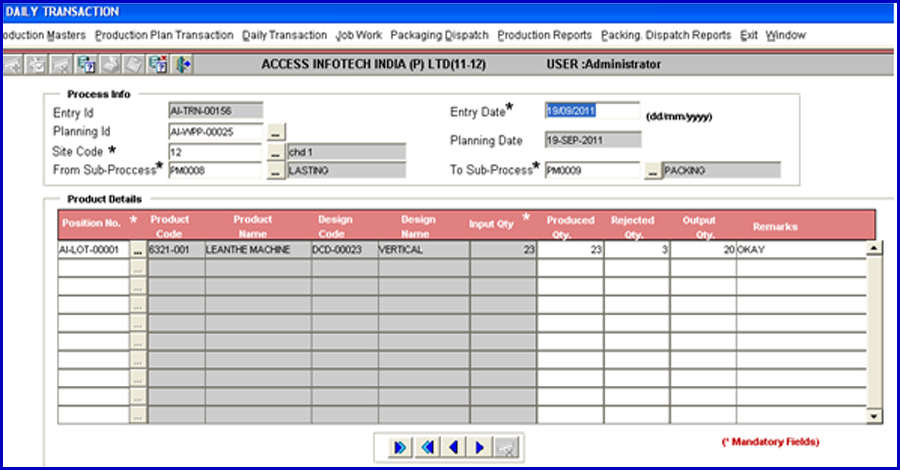

Daily transaction

The Daily cutting transaction is made for recording the daily transaction of cutting material in production process on daily basis.

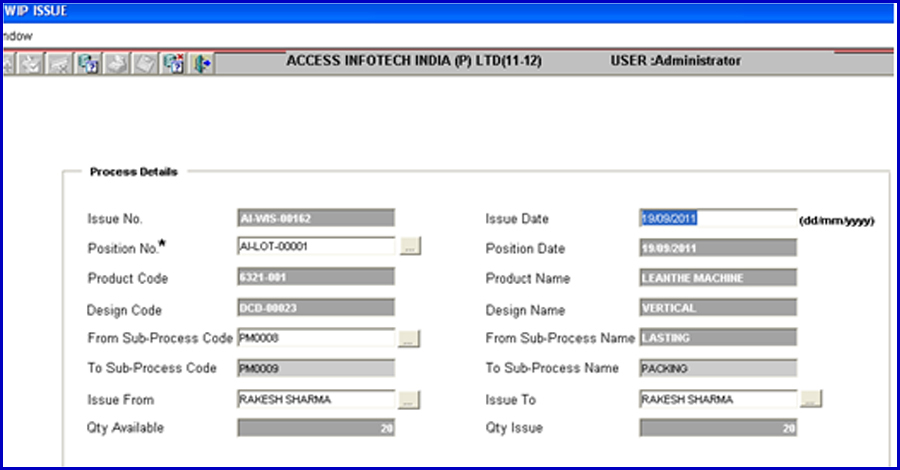

WIP Issue

The WIP Issue is made for issuing the output of one process to the input of next process in daily transaction so that material transfer can be controlled in work in progress from one process to another process.

Job work order

The Job work order form is made for assigning the Job work to supplier for production according to the Lot.